When it comes to the inner workings of a dirt bike, the number of pistons can be a defining factor in its performance.

Have you ever wondered how many pistons are actually in a dirt bike engine?

The answer might surprise you and shed light on the intricacies of these powerful machines.

Let's explore the relationship between pistons and engine configurations in dirt bikes to uncover how this element impacts the overall ride and maintenance requirements.

Key Takeaways

- Most dirt bikes have a single piston in their engine for simplicity and efficiency.

- The number of pistons directly impacts power characteristics and maintenance requirements.

- Single-cylinder bikes are favored for reduced maintenance, while multi-cylinder bikes offer enhanced power.

- Understanding the piston configuration is crucial for optimizing performance and selecting appropriate upgrades.

The Basics of Dirt Bike Pistons

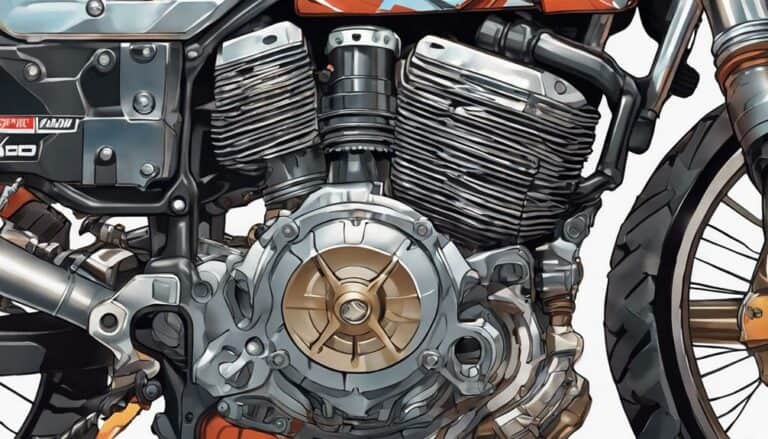

Most dirt bikes are equipped with a single-cylinder engine, typically featuring one piston. This piston is a vital component responsible for generating power within the engine. As the piston moves up and down inside the cylinder, it creates the necessary force to drive the bike forward. The design of a single-cylinder setup is favored in dirt bikes for its simplicity and effectiveness in delivering power efficiently.

Dirt bike pistons are commonly crafted from aluminum alloy. This material is preferred due to its lightweight properties, which reduce overall engine weight and enhance performance. Additionally, aluminum alloy pistons offer excellent durability and heat dissipation capabilities, vital for withstanding the high speeds and extreme conditions encountered during off-road riding.

Regular maintenance and inspection of the piston in your dirt bike are vital to ensure top performance and longevity. Keeping the piston clean, checking for wear and tear, and replacing it when necessary are essential steps in maintaining the engine's efficiency and reliability. By understanding the importance of the single-cylinder piston in your dirt bike, you can enjoy a more liberating and thrilling riding experience.

Understanding Single Vs. Multi Piston Setups

When considering dirt bike engine configurations, it's essential to understand the distinction between single and multi-piston setups for optimizing performance and power delivery.

- Single-Cylinder Engines

Single-cylinder engines are common in dirt bikes for their simplicity and lightweight design, making them ideal for smaller displacement models. They provide a good balance of power and efficiency, suitable for beginners or riders who prefer agility over raw power.

- Multi-Cylinder Engines

Multi-cylinder engines, found in some high-performance dirt bikes, feature 2 or more pistons. These setups offer increased power output, torque delivery, and overall performance, making them well-suited for riders looking for maximum power and acceleration on challenging terrains.

- Piston Configuration Impact

The number of pistons in a dirt bike engine directly influences its power characteristics. Understanding the piston configuration is critical for maintenance, tuning, and tailoring the bike's performance to specific riding conditions, ensuring the best power output and efficiency.

Performance Impact of Piston Configuration

The performance of a dirt bike is greatly influenced by the configuration of its pistons, impacting power delivery, torque output, and overall riding dynamics. Single-cylinder dirt bikes, with their straightforward design, are favored for their simplicity and reduced maintenance needs. On the other hand, twin-cylinder dirt bikes are known for providing smoother power delivery, enhanced balance, and increased performance due to the presence of two pistons working together. The choice between a single or twin-cylinder setup can noticeably affect power delivery, torque characteristics, and the overall riding experience based on your preferences. Riders must comprehend the piston configuration in their dirt bike engine to optimize performance, choose appropriate aftermarket parts, and make well-informed decisions regarding maintenance and upgrades.

| Aspect | Single-Cylinder | Twin-Cylinder |

|---|---|---|

| Power Delivery | Generally more abrupt but can vary based on engine tuning | Smoother delivery due to two pistons working in coordination |

| Maintenance Needs | Lower due to simpler design | Higher due to increased complexity |

| Aftermarket Support | Abundant options available for customization | Wide range of performance-enhancing parts |

Exploring Piston Sizes in Dirt Bikes

Exploring the diversity in piston sizes within dirt bikes reveals a nuanced relationship between engine performance and design intricacies. When delving into the world of piston sizes in dirt bikes, there are several key factors to take into account:

- Piston Size and Engine Displacement: The size of the piston in a dirt bike engine is intricately linked to the engine's displacement. Larger engine displacements often require bigger bore sizes and pistons to generate increased power and torque.

- High-Compression Pistons for Enhanced Performance: Performance dirt bikes may opt for high- compression pistons in order to achieve heightened power output and improved throttle response, especially in competitive racing scenarios.

- Tailored to Riding Styles and Terrain Conditions: Different dirt bike models come equipped with specific piston sizes and configurations to meet varied riding styles and terrain conditions. Whether you prefer motocross, enduro, or trail riding, there's a piston size designed to optimize performance based on your specific needs.

Maintenance Tips for Dirt Bike Pistons

To properly maintain dirt bike pistons, thorough inspection for wear, scoring, and damage is essential. Check the piston rings for proper seating and signs of wear to guarantee ideal engine performance. Measure the piston clearance accurately, adhering to the manufacturer's specifications for reliable operation. Before reinstallation, clean and lubricate the pistons meticulously to prevent premature wear and enhance longevity.

Be vigilant for any signs of wear, scoring, or damage on the pistons. If you notice excessive wear, damage, or experience reduced performance, consider replacing the pistons promptly to maintain peak dirt bike performance. Installing a new piston can significantly enhance engine efficiency and power output.

Regular maintenance and proactive replacement of pistons when necessary are key to ensuring your dirt bike operates at its best. By following these maintenance tips diligently, you can prolong the lifespan of your dirt bike's pistons and enjoy consistently high performance on your rides.

Conclusion

You now have a better understanding of the importance of pistons in a dirt bike engine.

Did you know that a high-performance dirt bike engine can have pistons reaching speeds of up to 14,000 RPM?

This statistic showcases the incredible power and precision required to keep a dirt bike running at its best.

Remember to stay on top of upkeep to make certain your pistons continue to perform at their peak.