When it comes to checking the bottom end bearings on your dirt bike, starting with a thorough inspection of the connecting rod is important. However, before you jump into dismantling the engine, there's a simpler way to assess the condition of these critical components.

By paying attention to certain indicators and utilizing specific tools, you can gain valuable insights into the health of your bike's bottom end bearings. But how do you go about this process efficiently and accurately? The answer lies in understanding the signs of wear, the steps for inspection, the necessary tools, and the implications of bearing wear.

Key Takeaways

- Listen for abnormal noises, vibrations, and performance changes.

- Inspect bearings for wear, damage, and proper clearance.

- Utilize specialized tools like dial indicators and micrometers.

- Replace bearings if signs of heat buildup, pitting, or scoring are present.

Signs of Worn Bottom End Bearings

To identify signs of worn bottom end bearings on your dirt bike, listen for abnormal knocking noises while the engine is idling. These noises can indicate that the bearings are worn out and need attention. Additionally, pay attention to any vibrations felt through the bike, as this could be a sign of loose or failing bottom end bearings. If you notice leaking crank seals, this is another important indicator that the bottom end bearings may need rebuilding.

When it comes to symptoms of approaching bottom end wear, be on the lookout for decreased engine performance or unusual engine behavior. Increased engine noise or issues starting the dirt bike could also signal worn bottom end bearings. It's important to make sure that these signs aren't ignored, as addressing them promptly can prevent further damage and the need for more extensive repairs down the line.

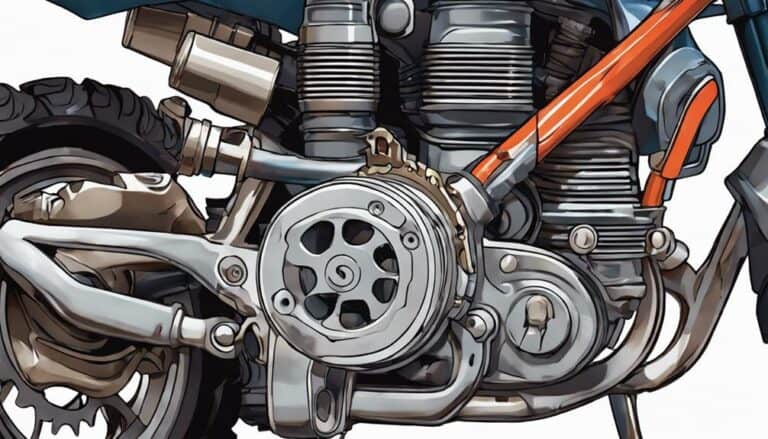

Step-by-Step Bottom End Inspection

Inspecting the bottom end bearings on your dirt bike involves a systematic process to guarantee important function and prevent potential issues. To begin, you must first remove the top end to gain access to the bottom end bearings.

Once exposed, carefully inspect the bearings for any signs of wear, damage, or excessive play. Utilize a feeler gauge to measure the clearance between the bearings and the crankshaft, ensuring it falls within the manufacturer's specifications.

While rotating the crankshaft, be attentive to any abnormal noises, vibrations, or irregularities that could indicate bearing issues. Proper lubrication is important for the bearings' longevity and performance.

If any problems are detected during the inspection, it may be necessary important a bottom end rebuild to address issues such as a worn connecting rod. Timely maintenance and attention to detail in the inspection process can help prevent costly repairs down the line.

Tools Needed for Bearing Check

For a thorough inspection of the bottom end bearings on your dirt bike, make sure you have essential tools such as a dial indicator, magnetic stand, micrometer, feeler gauge, and flashlight. These tools are vital for accurately evaluating the condition of the bearings and determining if they need replacement. The table below summarizes the tools needed for checking the bottom end bearings of your dirt bike:

| Tools | Function |

|---|---|

| Dial Indicator | Measures axial play in the bottom end bearings. |

| Magnetic Stand | Keeps the dial indicator stable and aligned during the inspection process. |

| Micrometer | Checks the dimensions of the bearings to identify wear and tear. |

| Feeler Gauge | Assesses the clearance between the bearings and the crankshaft. |

| Flashlight | Illuminates hard-to-reach areas for a detailed inspection of the bottom end bearings. |

How to Interpret Bearing Wear

When examining bearing wear on your dirt bike, focus on identifying signs of discoloration, pitting, or scoring as indicators of potential issues. Discoloration, often a result of heat buildup, can signal excessive friction or insufficient lubrication.

Pitting, characterized by small craters or dents on the bearing surface, indicates wear and can lead to accelerated deterioration. Scoring, visible as grooves or marks, suggests abrasive particles or metal-to-metal contact, compromising the bearing's integrity.

In four-stroke engines, the top end is particularly susceptible to bearing wear due to higher RPM and combustion forces. To accurately assess wear, measure the inside diameter of the bearing and check for deviations from manufacturer specifications.

Additionally, inspect for play or roughness when rotating the bearings, and examine the cages for damage that may impact performance. Understanding these signs of wear is vital in maintaining the reliability and longevity of your dirt bike's bottom end bearings.

When to Replace Bottom End Bearings

To determine the appropriate timing for replacing bottom end bearings on your dirt bike, focus on recognizing specific indicators of wear and potential issues. If it has been a considerable amount of time since you last inspected or replaced the bottom end bearings, it's advisable to make sure they're completely functional.

Listen for any abnormal noises such as knocking or rattling emanating from the engine, as these can be signs of worn bearings. Excessive play or movement in the connecting rod is another clear indication that replacement may be necessary. Additionally, keep an eye out for leaking crank seals, as this can also point to bottom end bearing issues.

If you notice a significant increase in vibration or roughness while riding, it's recommended to inspect the bottom end bearings promptly. Remember, regular maintenance, including checking and replacing bottom end bearings, is essential to prevent costly damage and ensure peak performance of your dirt bike.

Conclusion

Inspecting and maintaining bottom end bearings on your dirt bike is important for optimal performance and longevity. By regularly checking for signs of wear and using the right tools, you can prevent costly repairs and guarantee a smooth ride.

Remember, a well-maintained bottom end means a smoother ride on the trails. Don't let worn bearings slow you down – stay ahead of the game and keep your dirt bike running at its best!