When it comes to maintaining your dirt bike engine, addressing the valve stem seals is a task that requires precision and attention to detail. As you consider the process of removing these seals, remember that having the right tools and a systematic approach is key.

Each step in this procedure plays a vital role in ensuring the best performance of your engine. Stay tuned to discover the essential techniques for successfully removing valve stem seals from your dirt bike engine and maximizing its longevity.

Key Takeaways

- Gather tools like a 13mm socket and needle nose pliers for valve stem seal removal.

- Inspect valve cover for wear and perform maintenance like a valve adjustment if needed.

- Extract old seals precisely with a small screwdriver and clean valve components thoroughly.

- Reassemble the engine carefully, ensuring proper lubrication and performing a valve adjustment for optimal performance.

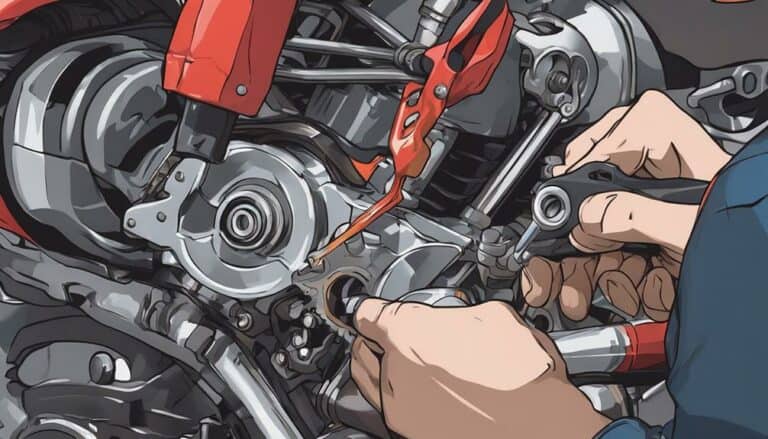

Tools Required for the Job

To begin the valve stem seals removal process on your dirt bike engine, gather the essential tools: a 13mm socket, a magnet, a parts tray, needle nose pliers, and a small screwdriver or dental pick. Place a piece of wood under the engine to support it and prevent damage. Using the 13mm socket, remove the bolts securing the valve cover. Carefully lift the cover to access the valve components.

With the magnet, extract the keepers, ensuring they're safely stored in the parts tray. Use the needle nose pliers to remove the spring retainers and carefully pull out the spring. Extract the valve, keeping track of its orientation for getting it back correctly later. The small screwdriver or dental pick can then be employed to take out the old valve stem seals.

Ensuring you have all the components organized in the parts tray will make getting it back together smoother. This methodical approach will help you stay on track during the reassembly process.

Removing the Valve Cover

Carefully employ a 13mm socket to begin removing the valve cover from your dirt bike engine. Once the valve cover is off, you will have access to the valves for inspection and potential seal replacement. This step is important to guarantee peak engine performance. Check for any signs of wear or damage on the valves and springs. If necessary, this is also a good time to perform any needed valve adjustment to maintain peak engine performance. Here is a table summarizing the key points for valve cover removal:

| Valve Inspection | Seal Replacement |

|---|---|

| Check for wear or damage on valves and springs | Replace seals if signs of leakage are present |

After completing the valve inspection and any necessary seal replacement, proceed with reinstalling the valve cover. Proper seal installation is essential to prevent oil leaks and maintain the engine's health. Remember to follow maintenance tips to guarantee longevity and peak performance of your dirt bike engine.

Extracting the Valve Stem Seals

When extracting the valve stem seals, utilize a small screwdriver or dental pick to carefully remove the old seals. Gently pry the seals off the valve stem to avoid damaging the surrounding components. It's important to make sure the area around the valve stem is clean and free of debris before installing new seals. Take your time during this process to prevent any pieces from falling into the engine, which could lead to further complications. Properly dispose of the old seals once removed.

For valve stem seal removal tips, remember to work methodically and patiently to avoid any mishaps. Common seal installation mistakes include rushing the process and not checking for a secure fit. To prevent seal damage, handle the removal tools with precision and care. By following these techniques, you can successfully extract the valve stem seals without causing any harm to the engine components.

Cleaning the Valve Components

Cleaning the valve components involves meticulously removing carbon deposits and dirt from the valves, springs, and retainers to guarantee peak performance of the engine. To ensure proper maintenance and enhance engine performance, follow these steps:

- Use a degreaser or solvent to break down grime and deposits on the valve stem seals and surrounding areas.

- Thoroughly clean the valve stem seals to ensure proper seating and function when reinstalled.

- Inspect the valves for any signs of damage or wear while cleaning to address any issues before reassembly.

- Properly cleaned valve components can improve engine performance and prevent oil leaks after valve stem seal replacement.

- Pay attention to detail when cleaning, as it can significantly impact the longevity and efficiency of your engine.

Reassembling the Engine

To reassemble the engine, position the coil back in its original place and secure the coil retainer tightly to hold it in position. Make sure the valve is flush within the engine, avoiding any protrusions. Use needle nose pliers to carefully set the keepers in place for the valve stem seals. Double-check that both keepers are securely in position before proceeding with the final steps of reassembly.

Prior to closing up the engine, confirm that all components are well-lubricated to promote proper functioning. When tightening bolts and screws, apply the proper torque specifications to prevent over-tightening or under-tightening, which can lead to issues down the line.

Additionally, after reassembly, it's vital to perform a valve adjustment to guarantee top-notch engine performance. By following these steps meticulously, you'll successfully reassemble your dirt bike engine, ensuring it operates smoothly and efficiently.

Conclusion

To wrap things up, removing valve stem seals from a dirt bike engine is a straightforward process that can save you money on professional services. By following the steps outlined and using the necessary tools, you can successfully extract, clean, and reassemble the valve components.

This DIY method is so simple, it's like taking candy from a baby. So go ahead and tackle this task with confidence!