As you prepare to embark on the journey of truing your dirt bike wheel, imagine the wheel as a compass guiding you through the rough terrains ahead. With each revolution, it ensures stability and control, allowing you to conquer any obstacle in your path.

But what happens when that compass loses its true north? How do you bring it back to its full potential?

In this guide, we will unveil the secrets of truing a dirt bike wheel, providing you with the knowledge and tools to restore balance and precision to your ride.

So, tighten your grip, because the adventure begins now.

Key Takeaways

- The tools needed for wheel truing a dirt bike include a spoke wrench, truing stand, rim strip, spoke torque wrench, and the dirt bike's service manual for specific instructions.

- Before starting the truing process, it is important to inspect the dirt bike wheel for proper installation of the rim strip, alignment of the valve stem hole with the hub, loose or broken spokes, and any misalignment from back and side angles.

- Disassembly of the wheel involves removing the tire and tube, carefully removing the rim strip, and adjusting the spokes on one side to correct lateral runout. If necessary, the rim or spokes may need to be replaced.

- Lacing the spokes involves inserting them into the hub flange, crossing them to the opposite side of the rim, ensuring even tension and alignment, maintaining a consistent pattern, and gradually tightening the nipples with a spoke wrench. Quarter turns and alternating between spokes help achieve even tension.

Tools Needed for Wheel Truing

To begin truing your dirt bike wheel, you'll need a set of essential tools. These tools will allow you to adjust the tension of the spokes and ensure that your wheel is perfectly aligned.

The first tool you'll need is a spoke wrench. This tool is used to tighten or loosen the spokes, which are the thin metal rods that connect the rim to the hub. By adjusting the tension of the spokes, you can straighten any wobbles or bends in the wheel.

Another important tool is a truing stand. This stand holds the wheel in place and allows you to spin it freely. The stand has gauges that measure the lateral and radial runout of the wheel, helping you identify any areas that need adjustment.

You will also need a rim strip, which is a protective strip that goes between the rim and the inner tube. This strip helps prevent the spokes from puncturing the tube. Additionally, a spoke torque wrench is recommended to ensure that you tighten the spokes to the correct tension.

Lastly, it's crucial to consult your dirt bike's service manual for specific instructions and torque specifications. This manual will provide you with valuable information on how to properly true your dirt bike wheel and ensure optimal performance.

With these tools and resources at your disposal, you can confidently tackle the task of truing your dirt bike wheel.

Inspection of the Dirt Bike Wheel

Inspect the dirt bike wheel using a truing stand to ensure it's securely mounted and ready for examination. Here are the steps to follow:

- Start by checking the rim strip to ensure it's properly installed and covering the spoke holes. Make sure there are no tears or damage that could cause the spoke nipples to poke through.

- Next, inspect the valve stem hole to ensure it's centered and aligned with the hub. Any misalignment could cause the wheel to wobble or affect the tire's inflation.

- Move on to examining the spokes. Check for any loose or broken spokes, and tighten them as necessary using a spoke wrench. Ensure that all the spokes have consistent tension to maintain the wheel's integrity.

- Use the truing stand to check for any lateral or radial runout in the wheel. Look for any side-to-side movement or up-and-down hop. Adjust the spoke tension using the spoke wrench to correct any runout and eliminate wobbles.

- Take a step back and inspect the wheel from the back and side angles. Look for any signs of misalignment, such as a bent rim or uneven spoke tension. Make quarter-turn adjustments to specific spokes as needed to eliminate any side-to-side movement or up-and-down hop.

Disassembly of the Wheel

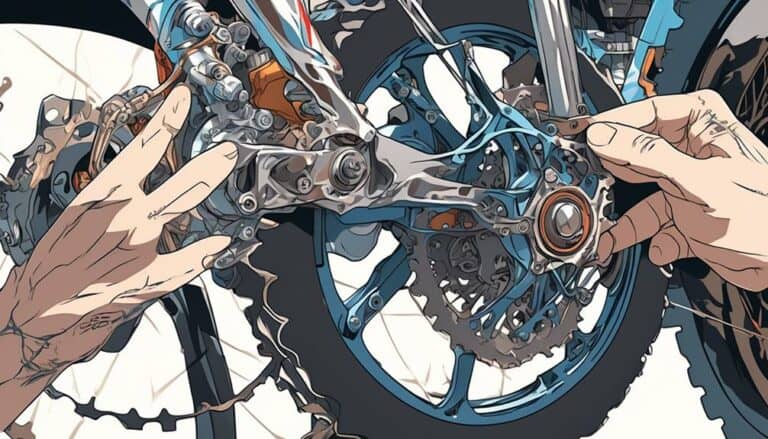

After thoroughly inspecting the dirt bike wheel, it's now time to disassemble it for further examination and adjustment. To begin, remove the tire and tube from the rim by deflating the tire and using tire levers to pry it off. Once the tire is off, carefully remove the rim strip, which is the protective strip that sits between the rim and tube.

Next, loosen the spokes on one side of the wheel by turning the spoke nipples counterclockwise with a spoke wrench. Start at the valve hole in the rim and skip two spoke nipples, then loosen the next one. Continue this pattern until all the spokes on one side of the wheel are loosened.

After loosening the spokes, use a spoke wrench to tighten the spokes on the opposite side of the wheel. This will pull the rim inward, helping to correct any lateral runout. Make sure to tighten the spokes evenly and incrementally, checking for any improvement in the wheel's trueness as you go.

If there's a significant bend or hole in the rim, you may need to install a new rim. In this case, you'll need to remove the rear wheel from the bike and replace the rim accordingly. You may also need to install new spokes if they're damaged or worn.

Lacing the Spokes

To properly lace the spokes of a dirt bike wheel, begin by securely positioning the wheel hub and aligning the spoke holes with the corresponding rim holes. Follow these steps to ensure a precise and liberating lacing process:

- Insert the spokes into the hub flange with the bend pointing towards the rim. Lace them through the corresponding rim holes, crossing them to the opposite side of the rim. Make sure to maintain an even number of crosses for each set of spokes.

- As you continue lacing, ensure the spokes are evenly tensioned and aligned. This will help keep the rim straight and centered on the hub. Maintain a consistent pattern and adjust the tension on one spoke at a time to achieve balance.

- Complete the lacing process by tightening the nipples with a spoke wrench. Gradually and evenly tighten them, avoiding excessive force that may warp the wheel. Remember to make only a quarter turn at a time and alternate between spokes to maintain an even tension.

Truing and Tensioning the Wheel

Now that the spokes have been properly laced, it's time to move on to truing and tensioning the dirt bike wheel. Truing refers to the process of aligning the wheel so that it spins evenly without any wobbles. Tensioning, on the other hand, involves adjusting the tension of the spokes to ensure they're evenly tightened.

To begin, mount the wheel securely on a truing stand. This will allow you to assess the lateral and radial runout of the wheel. Lateral runout refers to side-to-side movement, while radial runout refers to hop or up-and-down movement. Use a spoke wrench to adjust the tension of specific spokes, correcting any runout observed during the truing process.

Pay close attention to any hop or side-to-side movement as you make small, incremental adjustments to the spokes. It's important to work on specific spokes rather than tightening or loosening all of them at once.

Using a truing stand, check for any wobbles and ensure that the wheel is true. Repeat the truing process as necessary until the wheel spins evenly without any visible runout.

Remember to regularly maintain and inspect the trued wheel for proper spoke tension and signs of wear or damage. Consult the dirt bike's service manual for specific instructions and use a dial indicator to measure any runout.

Once the wheel is trued and tensioned, it can be mounted back onto the bike for optimal performance.

Conclusion

In conclusion, truing a dirt bike wheel requires careful inspection, disassembly, lacing of the spokes, and truing and tensioning the wheel. By using the right tools and following the steps outlined, you can ensure that your dirt bike wheel is properly aligned and balanced.

Just as a skilled painter delicately brushes each stroke to create a masterpiece, truing a dirt bike wheel requires patience and precision to achieve optimal performance.